At the Hoshizaki Group, research and development is central to how we create value. Working across regions and companies, we harness the collective expertise of our global teams to respond to the ever-changing needs of customers and industries worldwide. Our R&D efforts drive continuous innovation, not only to meet market expectations, but to anticipate future challenges and set new standards in foodservice technology.

Global R&D Hubs Driving Innovation

Collaboration Across Borders

Compliance and Beyond

Key Innovations

Internationally, we entered the U.S. market with our original crescent ice maker, featuring proprietary technology that produces Hoshizaki’s signature crescent-shaped ice. Across Europe, we have expanded with sustainable products designed to meet the region’s strict environmental standards.

To transform research and development into real-world solutions, we actively share best practices across our global network, evolving through collaboration and staying responsive to diverse market needs. This approach has enabled us to deliver industry-leading innovations that few can replicate.

We will continue to embrace new challenges and pursue excellence in innovation, creating a more sustainable and enriching future for people around the world.

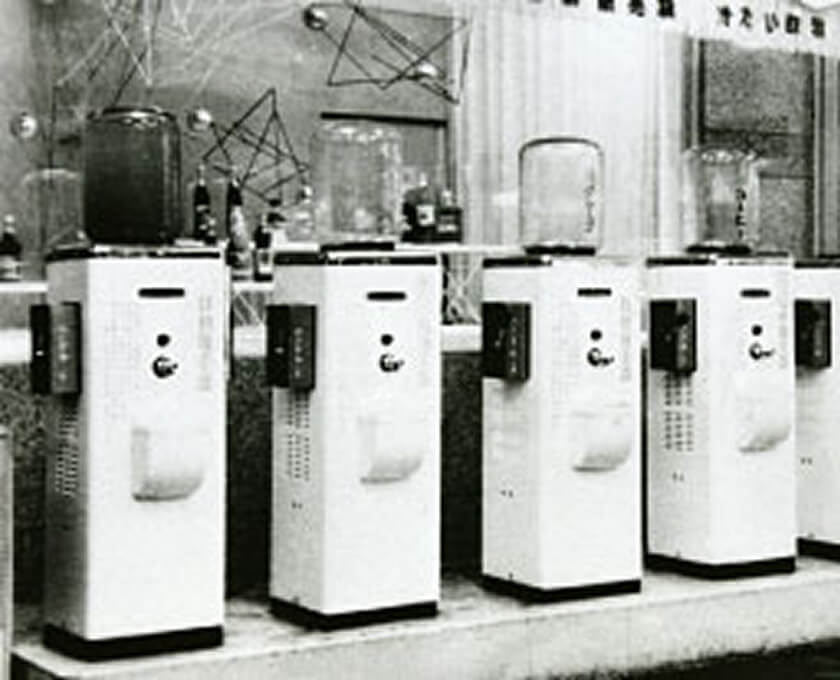

Japan’s First Juice Vending Machine

Inspired by water coolers in the United States, Hoshizaki developed its first water dispenser prototype in 1957. Soon after, the company was asked to create a machine that could dispense juice when a 10-yen coin was inserted for a public event.

Remarkably, within just ten days, Japan’s first juice vending machine was completed. The product was an instant success, and the technology developed from this challenge laid the foundation for Hoshizaki’s future refrigeration and cooling innovations.

Japan’s First Fully Automatic Ice Maker

In 1964, Hoshizaki developed Japan’s first fully automatic ice maker using proprietary ice-detection technology and began mass production the following year.

The machine produced clear, cube-shaped ice roughly three centimeters in size, which remains a symbol of Hoshizaki’s commitment to quality and innovation.

The First Inverter-Controlled Commercial Refrigerator

In 2005, Hoshizaki became the first in the industry to introduce inverter control to commercial refrigerators, dramatically improving cooling efficiency.

Energy consumption was reduced by approximately 60%, while lower waste heat helped reduce air-conditioning demand during summer months — a major step forward in environmental responsibility.

Japan’s First Mass-Produced Commercial Refrigerators with HFC-Free Insulation

In 2007, Hoshizaki became the first company in Japan to mass-produce commercial refrigerators using HFC-free foaming agents.

By converting more than 40% of annual production to cyclopentane-based insulation, the company significantly reduced its environmental impact. Today, all Hoshizaki Group commercial refrigerators worldwide use HFC-free insulation.

Commercial Refrigerators Using Natural Refrigerants

By adopting natural refrigerants such as propane and isobutane, Hoshizaki developed commercial refrigerators with exceptionally low Global Warming Potential (GWP).

First introduced in Europe in 2009, where environmental regulations are particularly strict, these products are now available globally, helping reduce environmental impact across markets.